Update: This activity has now ended. You can still see the results here and learn more about our work with repair data here. Thank you to everybody who took part!

Printers can be frustrating

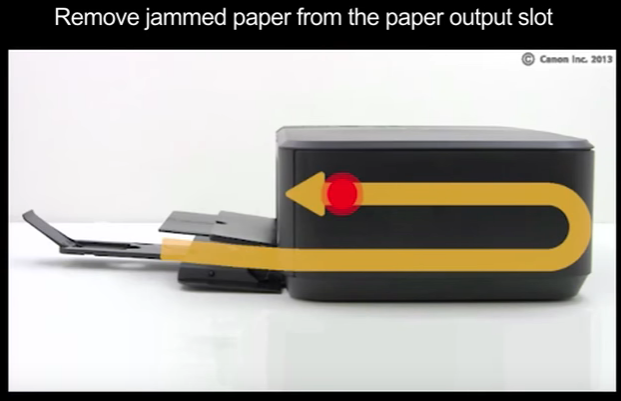

Unreliable, easy to break and hard to repair, printers are so often examples of devices that are just not designed to last. In fact, the average lifespan of printers today is as little as 4 years before becoming e-waste.

Change language | Cambia lingua | Changer la langue | Sprache ändern | andere taal | تغيير اللغة

Let’s change that

To celebrate Earth Day 2021, we’re launching PrintCat ![]() , a people-powered investigation into why printers break so often. We want to understand why printers fail so that we can tell policymakers how future models can be made to last longer and be easier to repair; repairable devices can reduce e-waste and lessen the strain on our planet’s resources.

, a people-powered investigation into why printers break so often. We want to understand why printers fail so that we can tell policymakers how future models can be made to last longer and be easier to repair; repairable devices can reduce e-waste and lessen the strain on our planet’s resources.

With PrintCat, you can join the investigation.

Together with our partners in the Open Repair Alliance, we’ve collected information on over 800 broken printers and we need your help to categorise them.

Go to PrintCat ![]()

How does PrintCat work?

-

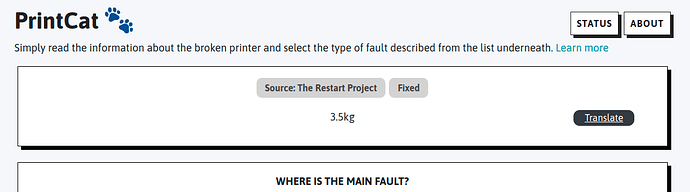

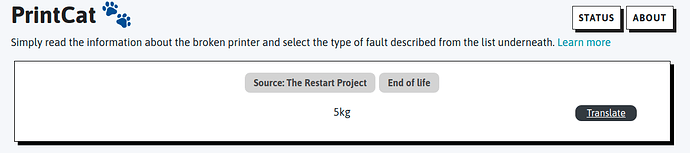

Go to PrintCat and choose your preferred language from the menu at the bottom right.

-

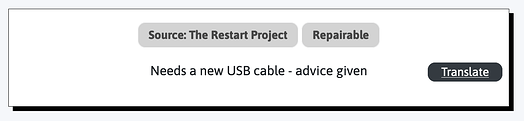

You will see some information about a broken printer that was brought to a real-life repair event (remember those?). Click the translate button to read it in your preferred language.

-

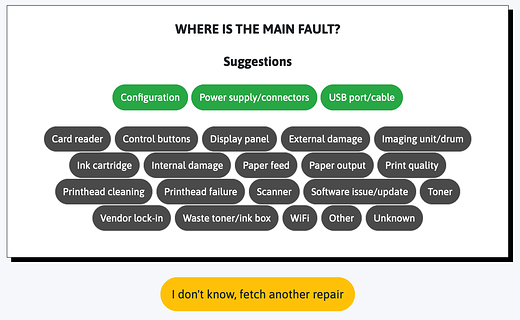

Select the type of problem that best describes the printer described from the list below the description and confirm your choice. If you’re not sure, just select ‘I don’t know’ at the bottom.

That’s it!

Once you’ve selected an option, you’ll see another printer. The more printer faults you can categorise, the more we learn! PrintCat shows each printer to three people to help confirm the right category.

Why printers, and why now

Consumer complaints suggest that many inkjet printers are thrown away after a lifetime of two to three years, with some being in use for as little as six months before they become e-waste.

– Coolproducts, 2019

Until now, there’s not been any regulation on printers’ repairability. In 2011, printer manufacturers signed a “voluntary agreement” with the EU, aiming to “reduce the environmental footprint” of printers, and exempting them from formal regulation.

Manufacturers are currently discussing a new version of the agreement, and the draft version we’ve seen is extremely weak on repair

If approved, this new voluntary agreement would allow manufacturers to refuse to make spare parts available for printers priced below €350.

What we hope to achieve

Most printers brought to community repair events fit in this category, so we thought it would be worth exploring why they fail. The European Commission could reject the voluntary agreement proposed by the industry, and decide to develop regulations on printers. We hope our findings will help make the case for more ambitious measures tackling repairability of printers.

And we also hope many people will enjoy contributing to PrintCat and learning more about why printers fail. PrintCat is the first in a series of three microtasks we’re running as part of our participation in the ACTION accelerator, engaging citizen scientists with open data. Over the next few months, there will be more opportunities to analyse data collected at repair events - so watch this space!

In the meantime…

Go to PrintCat ![]()

Questions? Comments? Feedback?

Great! Feel free to post below and let’s chat.

We are hugely grateful to to The ACTION (Participatory science toolkit against pollution) project for funding this work and for their support.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 824603. This post reflects the author’s views. The European Commission is not liable for any use that may be made of the information contained therein.