Do you have any examples of household appliances (large or small) coming to your event that have been deliberately designed to be unfixable in some way, or to break after a certain amount of time?

Bit of a gray area IMO - is the manufacturer using security screws while obviously a deliberate choice is it intended to make the device unfixable? On Saturday we had a toaster with security screws that the fixer couldn’t remove. Cheap toasters really do seem to be designed for a lifetime after which the filaments tend to fizzle out. CD players are always coming in where they can’t read a disc and using a cleaning disc doesn’t improve things because the laser has probably lost the power to sufficiently illuminate the nanometer dots on the disc.

I’d support the toasters example. I’ve sen numerous where removing the base is almost impossible and cannot be done using any sensible and readily available tools. It might be claims as a ‘safety feature’ but you have to almost destroy the toaster to access the electronics. Wish I could remember the maker (last example seen at Oxford RC).

At #fixfest-italia, someone brought along a small blender (a Moulinex Illico) that didn’t power on. It was designed in such a way that the entry point into the plastic casing that houses all the internal parts is also a part likely to come into contact with food & liquid, so was tightly sealed. So tightly in fact, that it proved impossible to open without doing irreparable damage to the casing.

Check it out in the repair navigator

While I don’t know whether it was designed to be unrepairable, it was certainly designed to make disassembly near-impossible for non-professionals.

This is super common with household electricals, and something we’ll probably try and raise with The One Show who are dropping into our Restart Party this Tuesday. Probably comes down to simply cutting costs in design and manufacture, as opposed to deliberate attempt to block repairs.

That said, Leyla Acaroglu says she had a formative experience as a young product designer being asked to design-in obsolescence in a toaster. Can’t find the clip. Wondering how common this is/was.

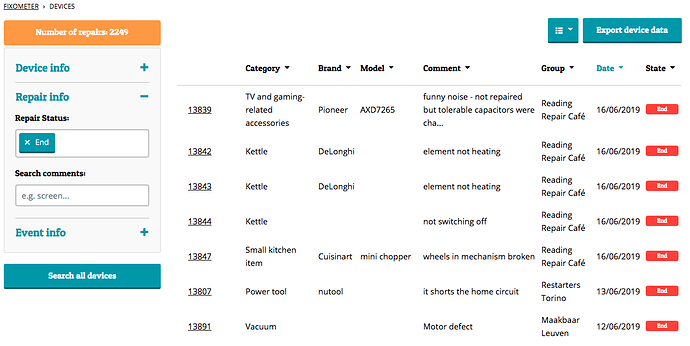

Wondering whether a search in the Repair Navigator

filtering for “end of life” then using the comment field for key words like “disassembly” “take apart” might help with this @Marie_Lefebvre? You have over 2,200 devices to learn from…

To be fair they wouldn’t be popular if people started getting ill from decaying stuff in the gaps between parts.

I haven’t had to try anything like that since my Braun toothbrush repair where opening it cold was difficult - later found a YT repair video where they dipped the joined parts in boiling water to soften the plastic to make disassembly easier.

I guess it’s possible the blender is assembled warm to encourage tight sealing from shrinkage during cooling of the assembled product. Maybe some judicious softening with hot air on the casing would make it easier to open with less damage? Might need some gloves though :-o

Because The One Show researchers literally just asked the same thing, here is the spreadsheet I’ve downloaded for them — using this search. You’ll notice that so many items lack a brand/model that we are left with a select few…

Difficult to open devices.csv (5.9 KB)

It is a common problem for what in Italy we call “minipimer”, usually they are impossible to open. One time with very kind owner we did ugly repair, breaking the plastic and at the end closing firmly with plastic clamps. Not beautiful but running and probably still used.

There are some really evil security screws. Try Googling “shear bolts” for one example - once the head has sheared off - that’s it! There are several patented security screws that need a very specific tool, that the company will only sell to purchasers of at least 10,000 screws.

In my experience, most steam irons can only be dismantled by breaking plastic. This is often due to spire nuts being pushed over plastic posts - I’ve yet to find a way to get these off without breaking the post. There are also plastic catches where there is no screwdriver access to release the plastic catch - the only solution is breaking the catch (if you can find it!)

Hi,

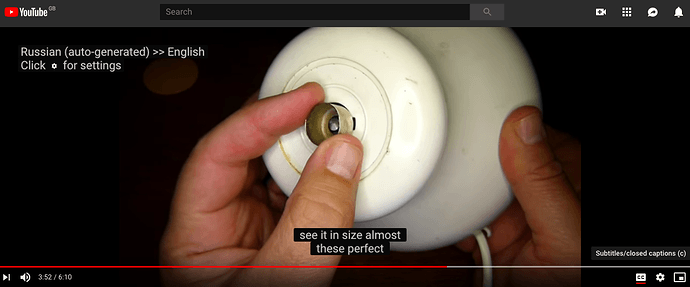

This ILLICO case resembles pretty much to a brother of it, the Multitrio:

We had it last week here. After trying with spudgers for a while, and thinking I would destroy it before finding the clips, I looked it up quickly in Google, and I found a video of a Russian guy (https://youtu.be/0i1S4PNSwUY). Although I got help from our Palestinian repairer who speaks Russian, but following the video it’s possible to reproduce it, not having a clue about the language ![]() . Basically, we used a screwdriver adapter, one of those cylindrical pieces to push from the top, just after removing the colour cover, and having the tool upside down, against the table, as he does from minute 3:36 (he uses a cylinder from a normal screwdriver, though). I am pretty sure it’s easier to understand on the video than with my explanation

. Basically, we used a screwdriver adapter, one of those cylindrical pieces to push from the top, just after removing the colour cover, and having the tool upside down, against the table, as he does from minute 3:36 (he uses a cylinder from a normal screwdriver, though). I am pretty sure it’s easier to understand on the video than with my explanation ![]()

Coming from the same company I wonder if the ILLICO could be also opened like that. I hope this is helpful for the next one in your hands, to try with a different approach ![]()

![]()

Ah ha! Thanks for that Angel! That’s definitely worth knowing for next time ![]()

@Sergio and @Antonio_Alessio_dikdust_D, Angel’s post above might be useful info for the repairer who attempted this fix at Fixfest Italia ![]()

Very true, not sure I’ve ever witnessed a successful iron disassembly/repair!

What an amazing story! Also just a tip about using YouTube’s automated captioning - for this video it works ok, not amazing but you can follow his main points

They got in touch through my university and they wanted to know the same answers to these questions. I told them that there are many variable to consider when defining an item’s repairability, so it is not straight forward to say that one item was designed purposefully to not be repaired and there is certainly a gap in research. Most studies that have been done on product lifetime expectation and item’s reparability rely on participants’ memory. it was the same issue in my investigation. they could not tell exactly which brands and model they dealt with. Hopefully, the european commision will force companies to use a scoring system to know whether their items are repairable or not and build a database from there which can be scrutinised using our own experience. Maybe, we could trial the scoring system for the item coming through the door?- https://ec.europa.eu/jrc/en/publication/analysis-and-development-scoring-system-repair-and-upgrade-products

had a look at the database, there are a few items that could not be disassembled enough - is it for lack of time, or simply because they could not. an item that cannot be disassemble did not presupposed that it was the end of its lifespan, the item was considered still repairable with the help of a professional. so can we say that items are designed not to be fixable. they are made to be difficult to fix for sure.

definitely a gray area- sometimes the manufacturers also want to avoid to endanger the user, so put barriers to repair. then there is technological obsolescence, where the item just wore out…

@Janet, good point, I knew about that, but I forgot

I’ve done a successful steam-iron repair.

The disassembly took about half an hour and was painful in all senses, since I had to wedge parts of the cover to get the rest of it open due to lots of plastic clips, trapping my fingers several times in the process.

Finding the problem (congealed scale & grease on the thermostatic switch) and fixing it took a minute or so,

reassembly took about 5 minutes.