Vacuum cleaners suck. At least, they’re supposed to. But we see quite a lot of broken vacuum cleaners at our repair events and they’re not always easy to fix. In fact, we’ve recorded over 1,000 attempts to repair vacuum cleaners between us here on Restarters. And that rises to over 3,000 when we also look at data collected by our partners in the Open Repair Alliance.

Now, the EU is writing new rules that could make vacuum cleaners easier to fix in the future. So we want to look at these attempted repairs in more detail to see what we can learn about the most common reasons vacuum cleaners break down. Knowing this could help us make a stronger case for effective rules from the EU, which could also influence the UK and other countries.

Introducing DustUp

DustUp is our latest people-powered investigation into why our devices break. This time, we want to learn the most common causes of failure for vacuum cleaners. To do this, we’ve partnered with students from the University of the Arts in London. Together, we’ll be reading through information about each of the broken vacuum cleaners in our database to determine the main fault.

UPDATE: DustUp is now complete. Thank you to everybody who took part!

You can help too! Simply visit DustUp below, read about some vacuum cleaners and try to identify the main reasons they broke:

How does DustUp work?

-

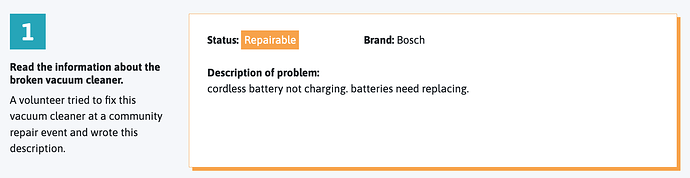

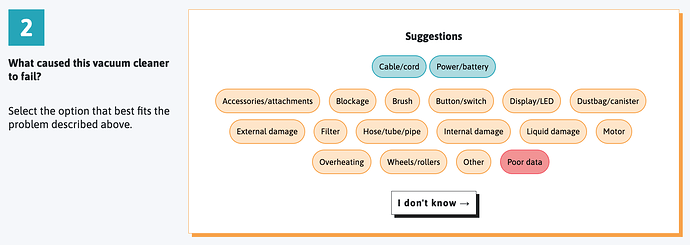

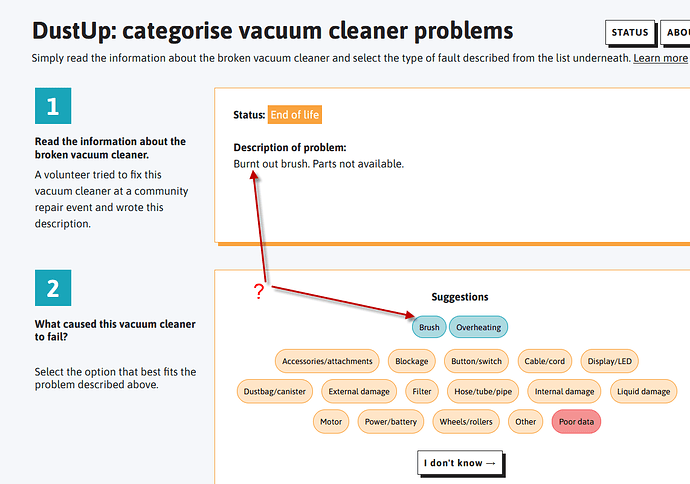

Go to DustUp. You will see some information about a vacuum cleaner that was brought to a real-life repair event.

-

Select the type of fault that best describes the problem. Once you’ve pressed an option, confirm your choice by pressing the “Go with…” button that appears at the top of the list. If the data provided is too poor quality to make a judgement, select the ‘Poor data’ button. And if you’re not sure, just select ‘I don’t know’ at the bottom.

That’s it!

Once you’ve confirmed an option, you’ll see another vacuum cleaner. The more faults you can categorise, the more we learn! And don’t worry if you’re not 100% sure about your answer: DustUp shows each vacuum cleaner to two or three people to help confirm the right category.

Why vacuum cleaners, and why now?

The European Commission ![]() is currently running a public consultation on Ecodesign and Energy Labelling for Vacuum cleaners.

is currently running a public consultation on Ecodesign and Energy Labelling for Vacuum cleaners.

This process will lead to a draft regulation on vacuum cleaners, including requirements on repairability and availability of spare parts. While the future legislation would only be binding for the EU single market, it’s likely to influence similar legislation in other countries around the world, including the UK.

So what can we do?

This is a unique opportunity to contribute data from people’s real-world experiences of recurrent faults in vacuum cleaners. European regulators tend to mostly have access to industry sources of data, so data from community repair initiatives is a precious addition to help make the case for repair.

This is why we need your help now!

Questions? Comments? Feedback?

Just post below and let’s chat ![]()